140 Jahre Gutekunst Verbindungsteile

Wir freuen uns über unser 140jähriges Jubiläum am 1. Dezember 2022 und bedanken uns bei unseren Kunden für die Treue und die gute Zusammenarbeit.

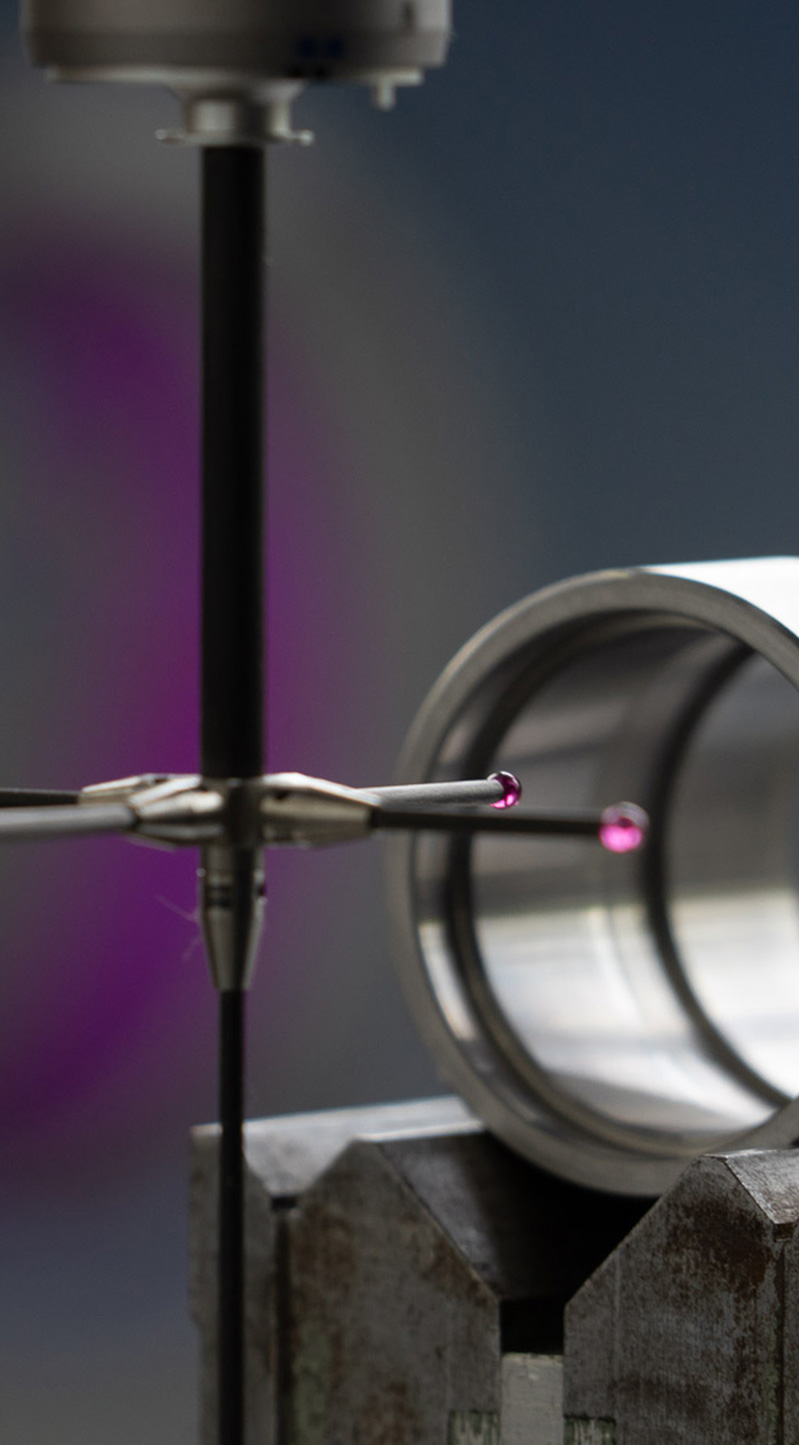

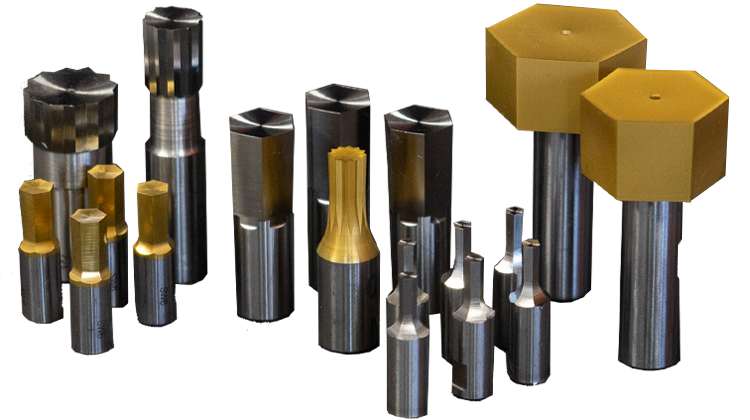

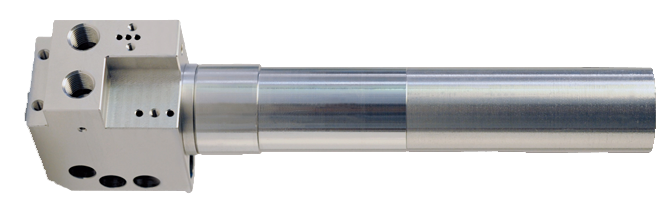

Räumdorne

Räumdorne in verschiedenen Ausführungen ab Lager, sowie auch individuelle Sonderprofil-Fertigung.

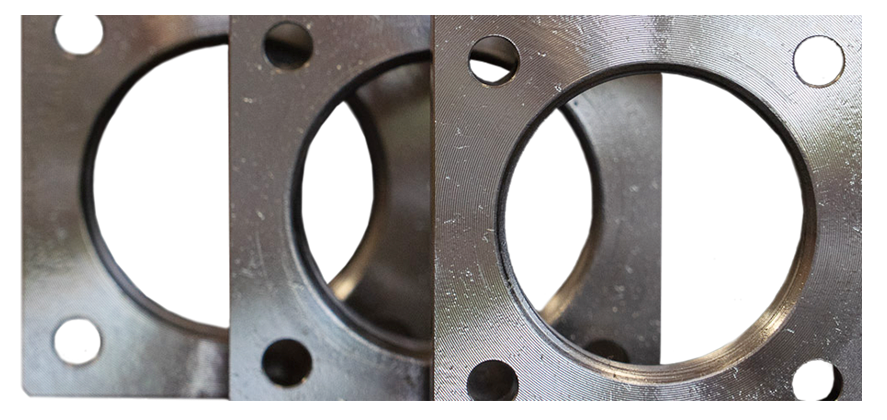

Serviceleistungen

Zink-Phosphat-Oberflächenbeschichtung sowie auch die Montage kompletter Komponenten.

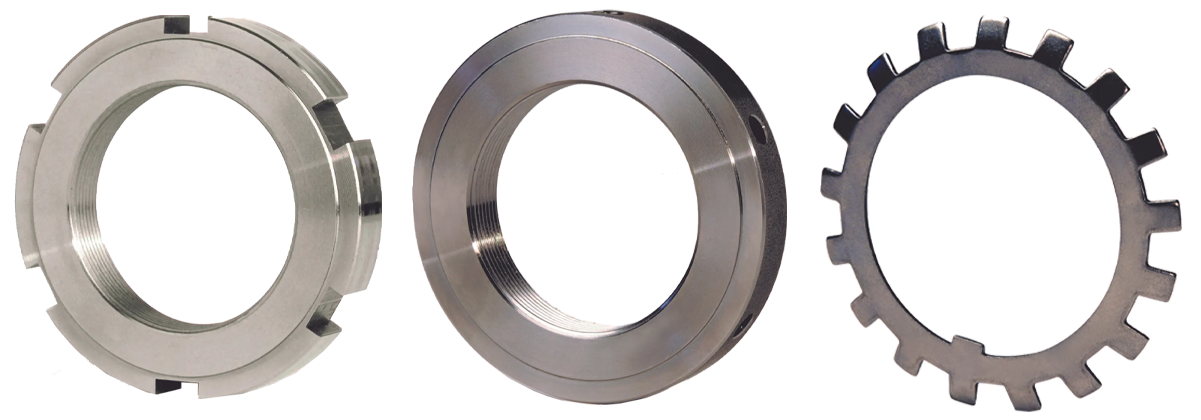

Wir sind Ihr Spezialist

für Norm- und Zeichnungsteile

Das Produktportfolio der Gutekunst Verbindungsteile GmbH wird stetig erweitert und den Bedürfnissen unserer Kunden angepasst.

Egal ob Normteil oder Zeichnungsteil – unsere Experten freuen sich auf Herausforderungen und beraten Sie auf höchstem Niveau.

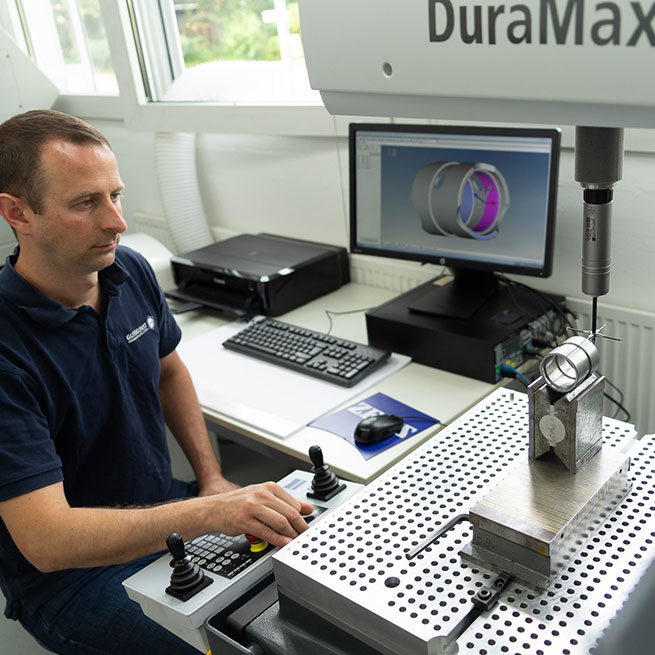

Wir verbinden Tradition und Innovation

Vom Einzel- zum Serienteil fertigen wir auf modernen CNC-Maschinen – Losgrößen vom Einzelstück bis zu mehreren 100.000 Stück pro Jahr. Wir freuen uns auf Ihre Anfragen!